Features

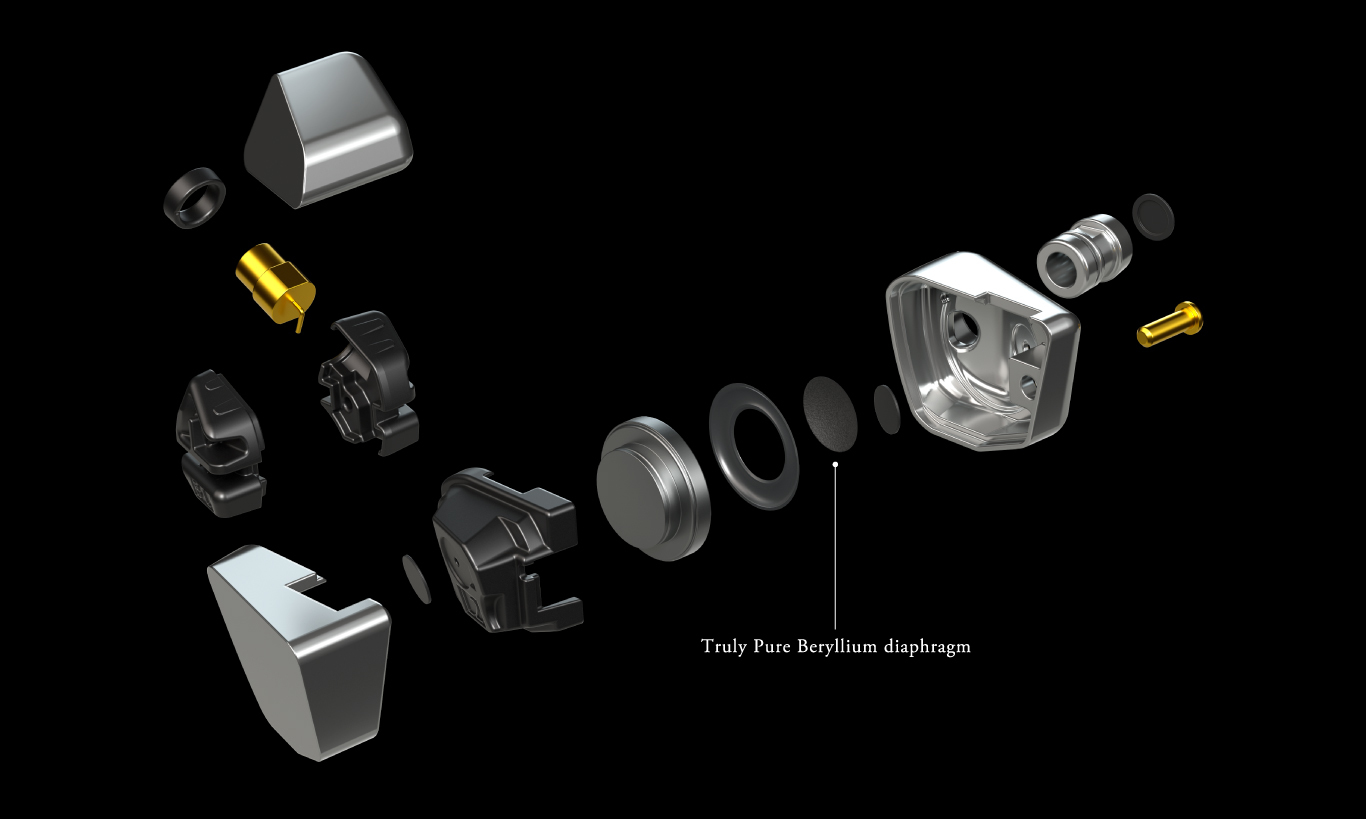

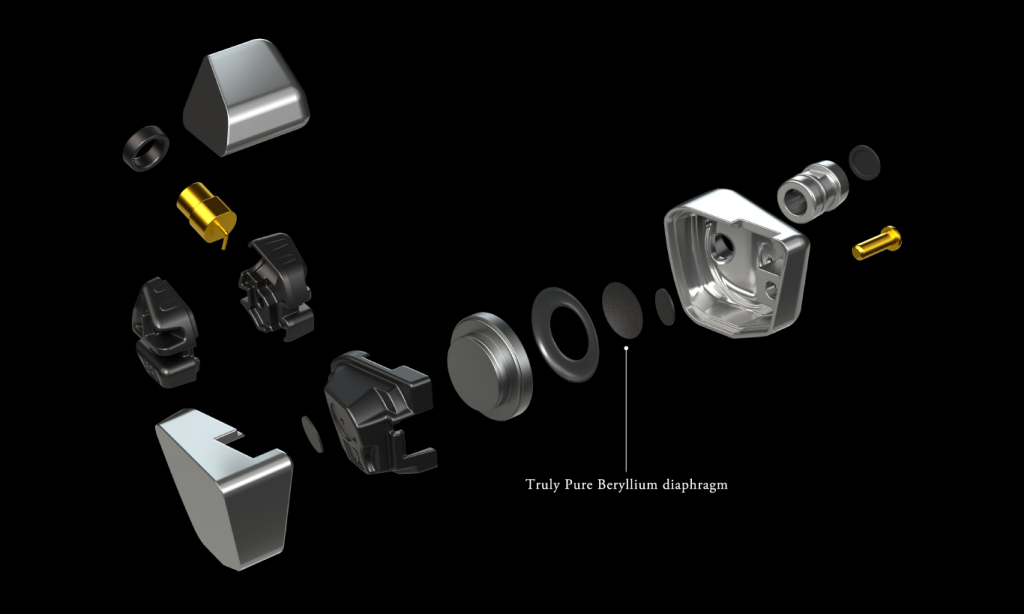

- A custom-made dynamic diaphragm made from ultra-thin Beryllium foil

- Suitable for a wide range of music from pop and rock to classical and jazz

- Ergonomic and organic IEM shape design with a superior comfortable fit

- Precisely cut stainless steel chassis with quad chamber construction

- Multi-chamber design achieves a balance between volume and bass response

- High-purity braided OFC silver-coated audio cable with MMCX connectors