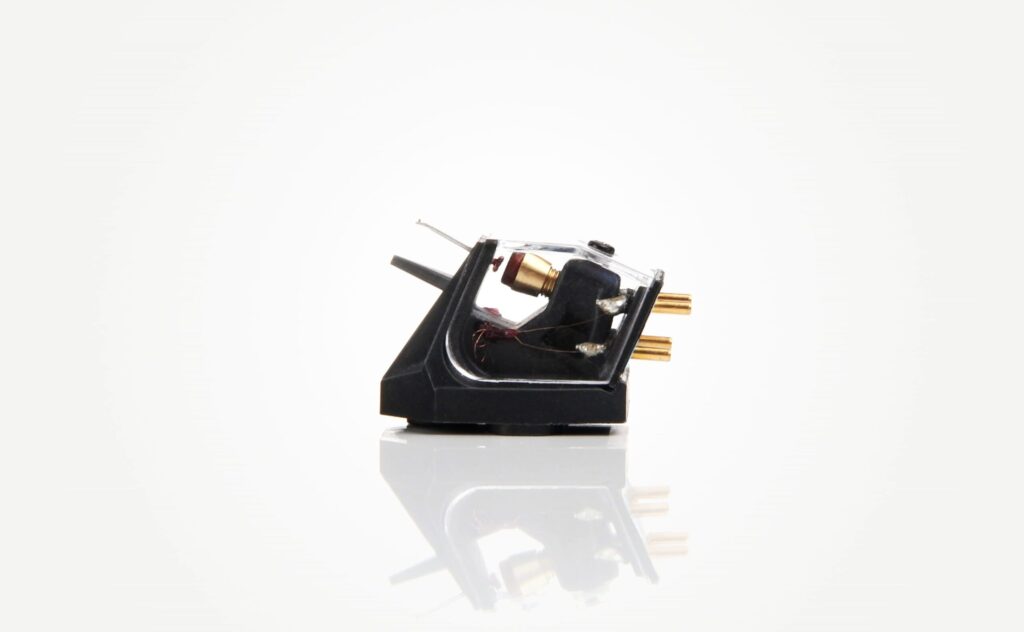

Features

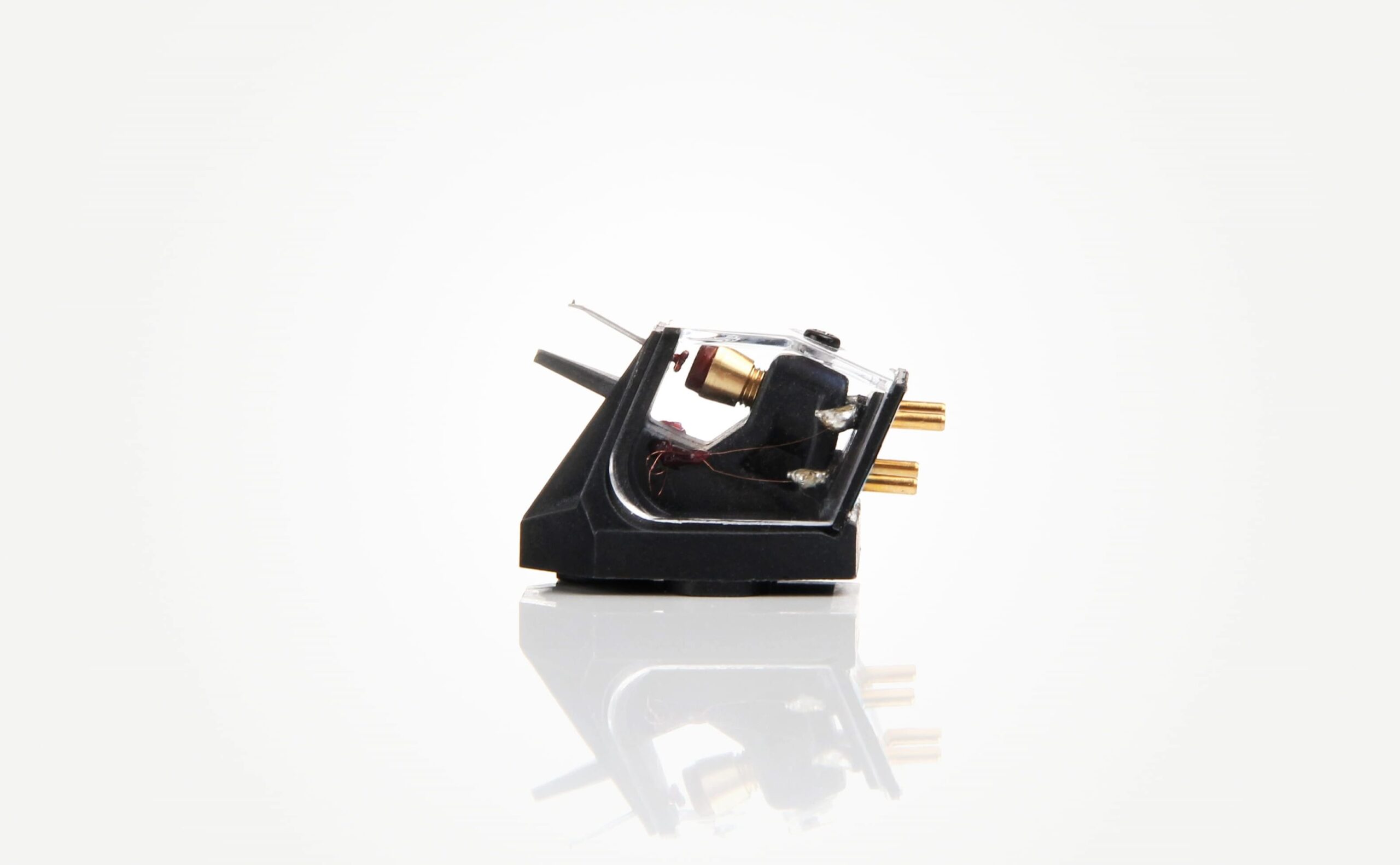

- Iron micro cross assembly

- One of the worlds smallest MC generators

- Cutting edge high power Neodymium magnets

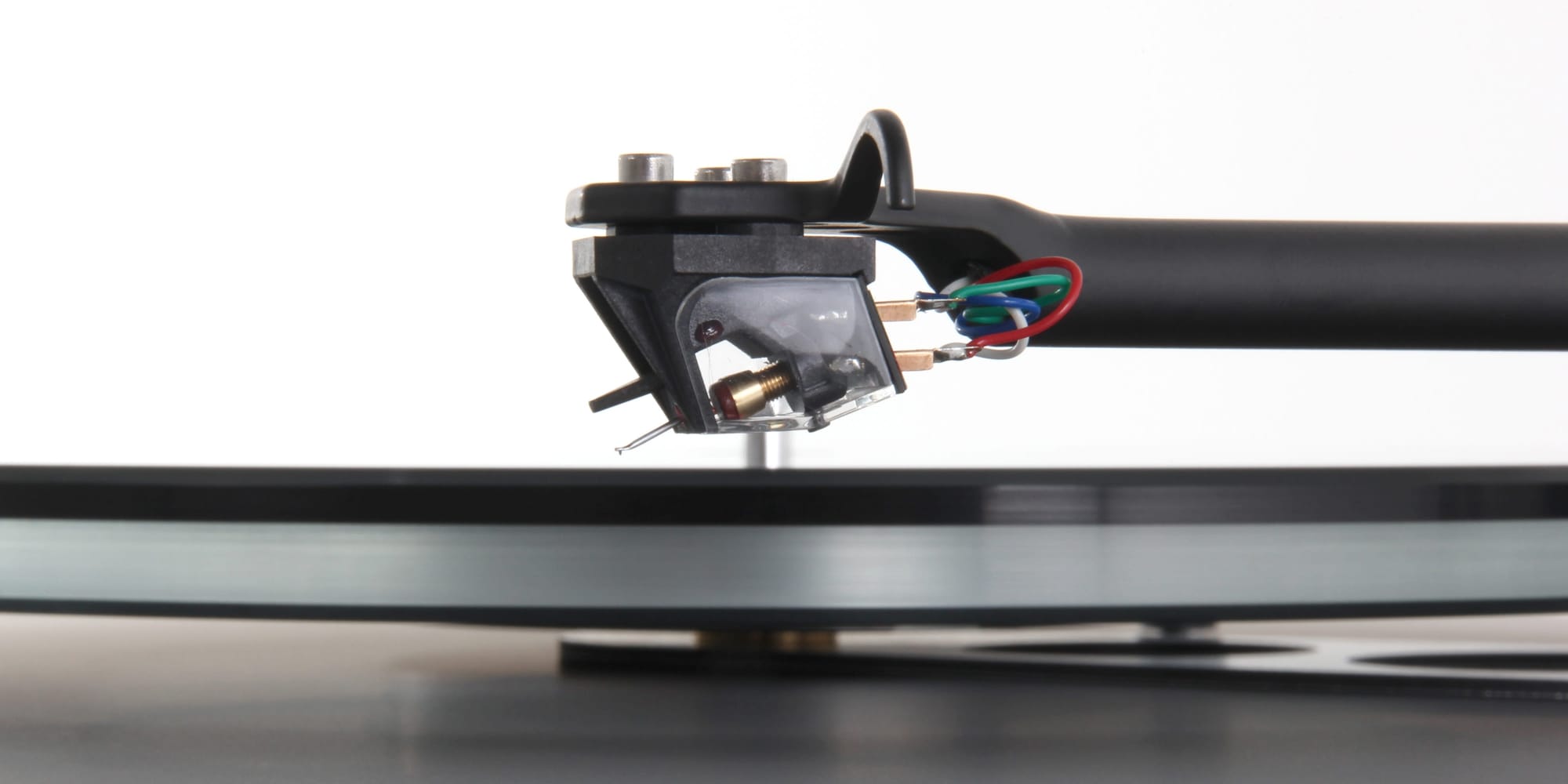

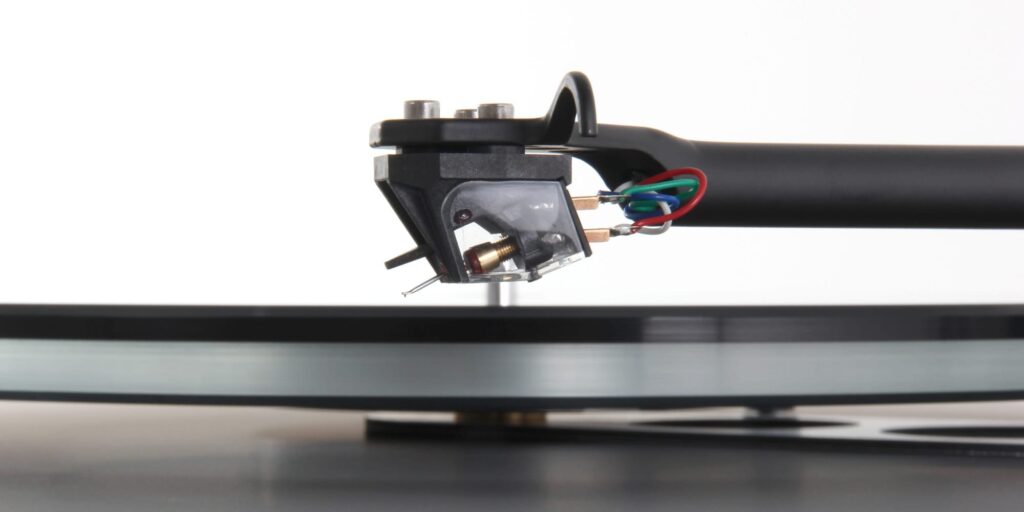

- Elliptical profile stylus

- Aluminium cantilever

- Coil constructed from 0.018 mm fine wire

- Lifetime warranty against manufacture defects