Features

- New flagship STAX earspeaker, 20 years of evolution since SR-Omega.

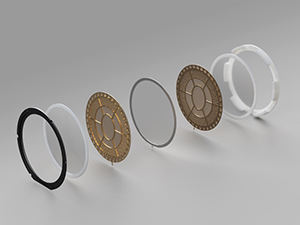

- Improved MLER-3 four-layer metal mesh fixed electrode.

- Diffused junction bonding.

- 20% increase in diaphragm size.

- Widest soundfield ever realised.

- Machined aluminium enclosure.

- Tilt mesh-guard design.

- Stainless steel arc with fully adjustable click system.

- Genuine leather earpads.

- Ultra-pure low-capacity wide hybrid 6NBu cables.